Tackling the crises of climate change and affordable housing calls for streamlining and industrializing the process for delivering deep retrofits. Europe is already retrofitting buildings with fully finished panels — complete with windows and integrated mechanical, electrical, and plumbing systems — and North American leaders are quickly making strides with prefabricated panel retrofits.

Download the primer, or keep reading below.

Find more resources to help local governments accelerate deep retrofits.

State of the North American market

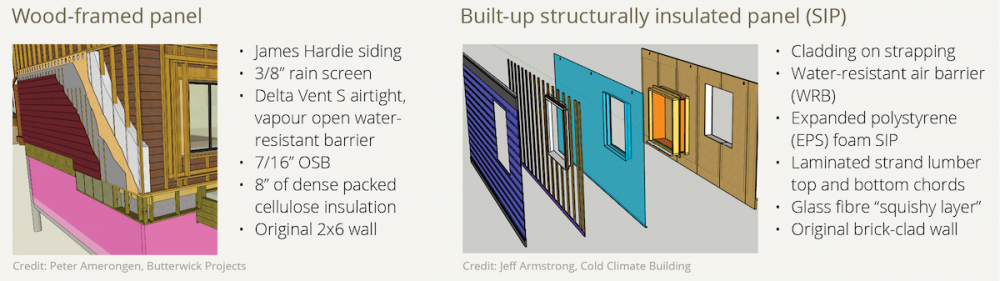

In recent years, modular housing and the prefabrication of wall panels for new construction have gained considerable momentum. Building on that experience, innovators are introducing prefabrication to building retrofits. Two examples of fully finished panel designs being implemented are illustrated below. The first is wood-framed with cellulose insulation, chosen to minimize cost and carbon footprint. The second integrates cladding and a water-resistant barrier with a structural insulated panel (SIP), chosen to minimize weight, plus the foam doubles as the air barrier. Both are installed directly over existing cladding to save time and minimize demolition waste, leaving potentially hazardous materials undisturbed. A “squishy layer” is sometimes added to improve contact with the existing cladding.

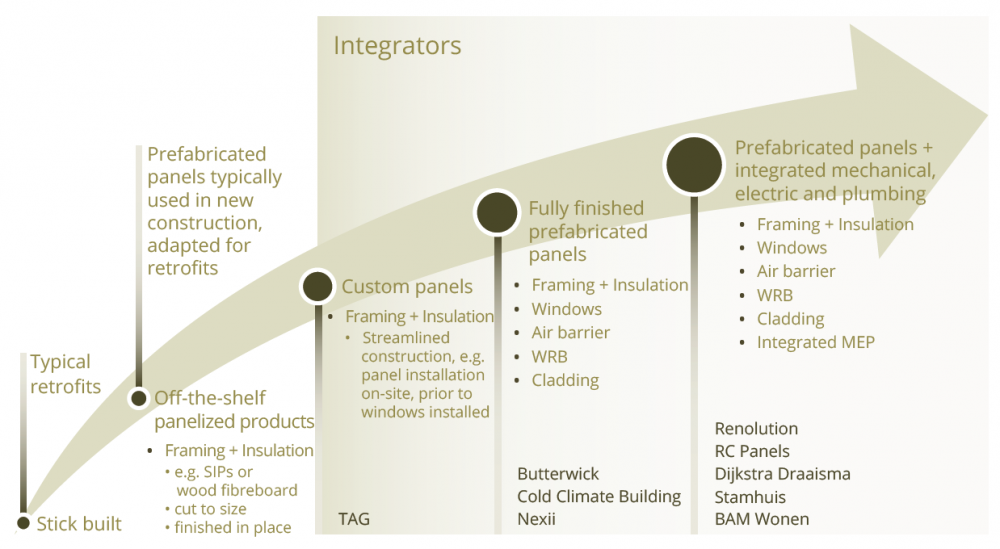

The prefabrication sector is beginning to recognize the opportunity existing buildings represent. In the meantime, retrofitters are taking the lead by playing an intermediary fabricator role, starting with basic prefabricated panels and integrating windows, water-resistant air barrier (WRB), and cladding — either on-site, immediately prior to installing the panel, or off-site, before delivery. Third-party integrators are launching demonstration projects throughout North America to help transform the retrofit process from stick built (assembled on-site) to fully prefabricated panelization with integrated mechanical, electrical, and plumbing distribution and equipment, as European companies are already doing.

Advantages of prefabrication

Prefabrication shifts the majority of construction off-site to a controlled environment, which can mean:

- Less time on-site and less disruption to occupants

- Lower risk of costly construction delays caused by inclement weather

- Reduced need for lay-down space on-site

- Better co-ordination of subcontractors and the supply chain

- Less demolition and construction waste

- Higher quality construction

- Safer working conditions

- Less demand on an already stretched labour force

Getting to prefabricated retrofits

A potential innovation path is proposed below, featuring examples of companies delivering solutions at each stage:

To industrialize the retrofit process, industry needs to hone new skills and adopt new approaches in:

- Assessing construction type, performance, condition, and preparation of a building

- Capturing building dimensions digitally using lidar or photogrammetry

- Working with point clouds and converting them into dimensioned drawings

- Streamlining preparation, construction processes and construction sequencing

- Improving panel fit and envelope continuity between panels and at the roof and foundation walls, and around windows and doors

- Attaching the panels to the existing structure and supporting their weight

- Integrating mechanical, electrical, and plumbing (MEP) distribution and equipment in prefabricated panels

- Co-ordinating and liaising with occupants in place

- Satisfying local permits and inspection of prefabricated panel design and installation

To facilitate this market transformation, the Pembina Institute is preparing projects that demonstrate the feasibility of whole-building retrofits.

Key considerations

- How can prefabricators adapt their designs and practices to enter the building retrofit space with cutting-edge solutions?

- How do designers balance the trade-offs between cost, weight, embodied carbon, and material availability in prefabricated panel solutions?

- What is the market scale needed to attract research and development (R&D), and how can governments and third-party integrators help?

Join a webinar

The Pembina Institute presents the Reframed Tech Series — webinars on evolving deep retrofit solutions. Watch our first webinar to hear from leaders in prefabricated panel solutions.

The Pembina Institute is leading an initiative to scale up deep retrofits for healthy, safe, and low-carbon housing. This is an opportunity for companies to showcase innovation and get in on the ground floor of a market transformation. Learn more.